RO/DI units

When putting together this write-up, I used information that I researched / collected from: Perfect Life Water, Water Filters On-line, Rocky Mountain Discus on-line, Watts Canada, and Honeywell Canada along with my personal experience.

First a little history (to skip the history part if you are not interested, just click on “continue reading” below and scroll down to the first diagram)

The osmosis process was first discovered inthe 1700s by a French Scientist whom observed water diffusing spontaneously through a pig bladder. In nature, contaminant which dissolved into water normally exists in the form of ions (commonly referred to as salt). A pig bladder is lined with a membrane that has small enough pore sizes that will not allow the transfer of salt ions, but large enough to still allow the water molecules to pass through. This is used as a separation medium between water having two different concentration of salt. Water will generally transfer from the least concentration side to the higher contamination side as equal concentration will give equal pressure.

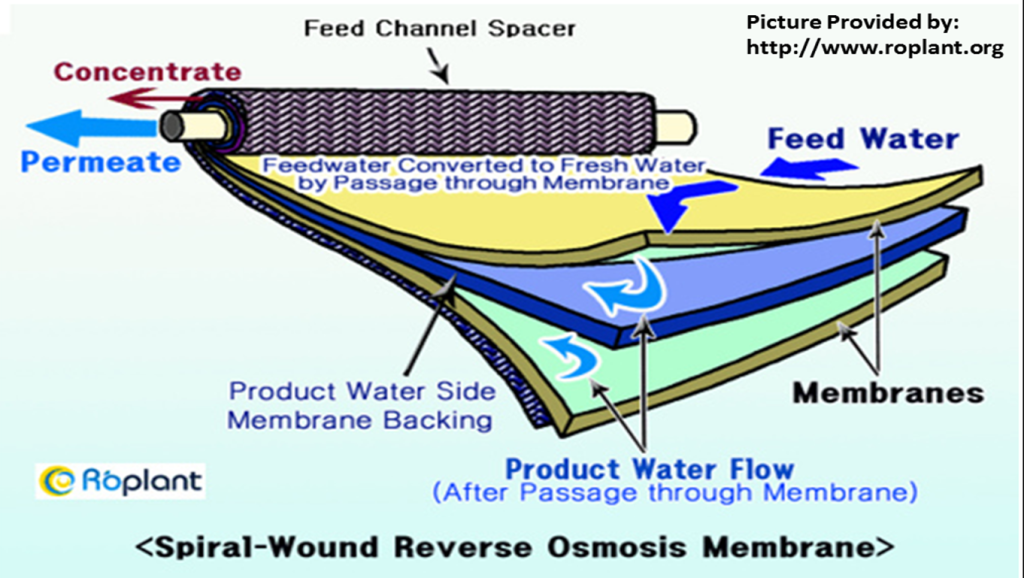

Applying water pressure to this process is known as osmotic pressure which is commonly referred to as osmosis. Reverse Osmosis filtering process work off the same principle. By applying pressure that is higher than the osmotic threshold pressure on the higher concentrated contaminant side of the filter, the water molecules will move to the lower concentration side of the filter, resulting in filtered and cleaner water.

Reverse Osmosis typically has a membrane style filter that works in the same way as the pig bladder. These filters have less than 5 angstrom (1 angstrom = 1/10,000,000th of a meter compared with human hair which is 750,000 angstrom diameter on average), the synthetic semi-permeable membrane used today will often use materials which have charge particles on its surface and will even reject more than 85% of the metallic and other polar molecules smaller than its opening. Compared with size of virus (which range in size from 90 to 1000 angstrom) and the size of bacteria (which has size in the range of 2000 to 2,000,000 Angstrom), the reverse osmosis membrane technology when installed properly and used with a check valve can effectively sterilize the water.

After the successful development of the semi-permeable membrane over forty years ago, the first Reverse Osmosis (RO) water filtration systems were developed. Originally the purpose for most RO filter systems was for the desalination of seawater as an alternative to distillation which is very expensive process.

In mid 1970s, the first residential low pressure semi-permeable membranes were developed and available to the public. These earlier systems were capable producing 1 to 5 gallons per day of filtered water for small households. With continuing advancements, the capacity of such low pressure systems can now provide up to 100 gallons per day, more than enough to meet the needs of a small family for all of their drinking and cooking needs as well as aquarium hobbyists alike. Because the reverse osmosis filters are rated in output range of 50 to 100 gallons per day (24 hour period) , water does not pour out of the filter like you get from a household tap. The RO water is produced in a slow, steady, almost dripping stream. Adequate water pressure is usually not a problem with residential water supplies. The RO membranes used in these systems will require around 40 to 80 psi to operate at their rated efficiency (you have to check the requirements of each individual system as some are different than others). Some residential water supplies can get as low as 30 psi although that is not very common. On well systems or in areas with lower water pressure, a simple booster pump can be added to the system to add the required pressure, or to increase the water flow out of the RO unit.

With continuing development of space technologies, NASA has developed advancements in RO technology as the solution for providing safe water for space flight and as a critical component to recycle waste water (including human fluid discharge). In several large cities around the world, the local water authorities have invested heavily into these technologies for municipal water recycling programs due to increased demand for both natural water supplies and recycling efforts as these cities grow.

RO units (by design) waste a lot of water. The membrane usually has 4-6 times as much water passing by it as it allows though. Unfortunately, the more water wasted, the better the membrane usually is at rejecting pollutants. Also, higher waste water flows are usually associated with longer membrane life. What this means in practice is that 300 gallons of total water may be required to produce 50 gallons of purified water. Many people keep the rejected water from their RO unit for other uses such as watering houseplants or flower beds. My wife and I will do that as much as we can.

Some of the advantages of using a RO unit include:

1. Flexibility in where to install the unit

2. The process does not produce any contaminants to the environments.

3. The process is based on reliable and proven technology.

4. The system is typically install in-line without any added equipment (with most residential water pressures).

5. A RO unit will also disinfect the water

A RO unit in Detail

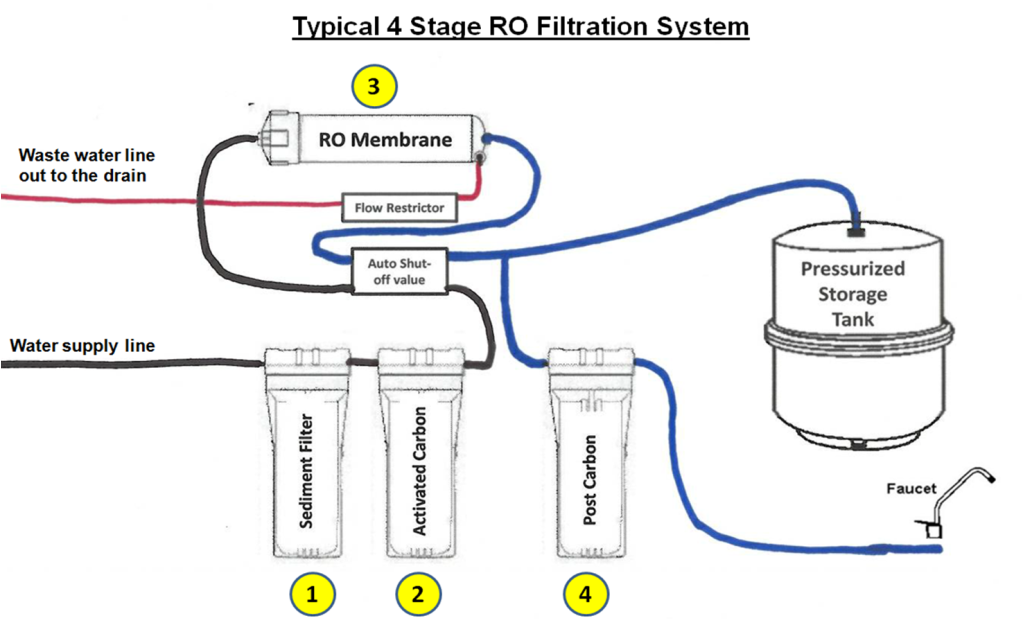

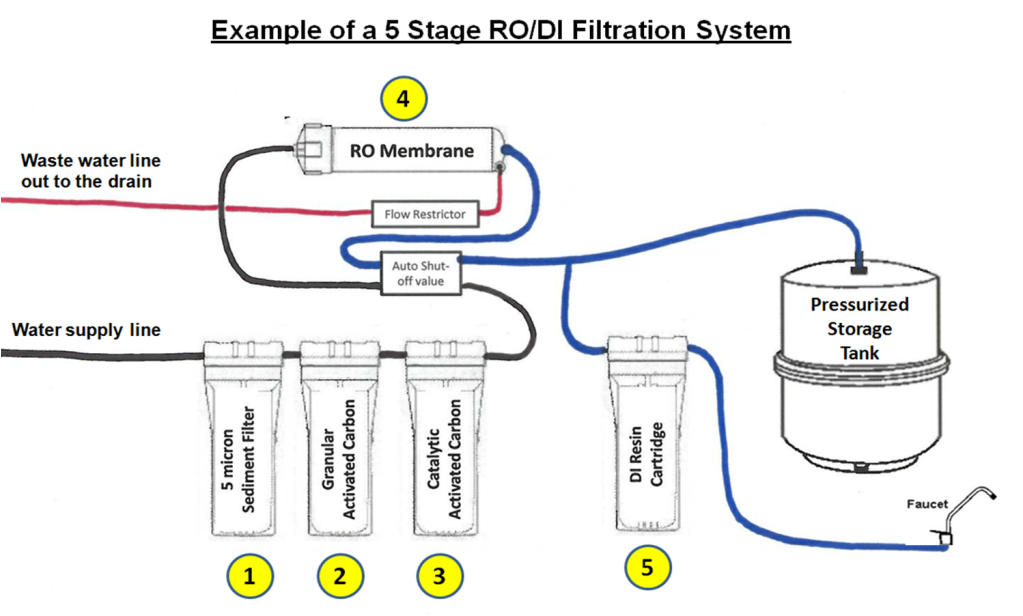

Domestic and commercial reverse osmosis systems in general, are actually referring to a series of somewhat different filtration methods used in combination to achieve the best possible quality in filtered supply. The typical (average) 4 stage RO set-up sold for household use is shown here. It is also described below.

Stage 1: Fine Particle/Sediment filter

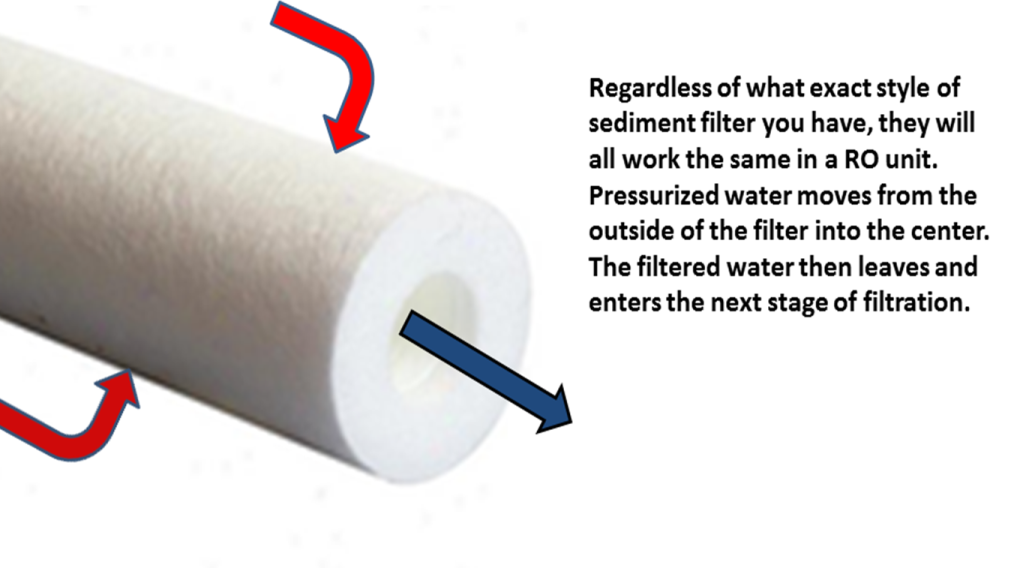

The very first stage of filtration is the sediment filter. There are many different styles of sediment filters but they are all measured by the same standard, the size of opening or size of particles that will pass through it. Most systems begins with a 5 micron sediment filters to screen out any large particulates including large iron silts, dust, and spores to name a few examples. This will prevent any large particles from getting onto the ultra fine RO membrane or carbon filters shortening their usable life. Sediment filters should be changed every 3 to 5 months depending on the quality of your water supply and usage. As with almost any type of filtration system, if you get better quality media you will get better quality water.

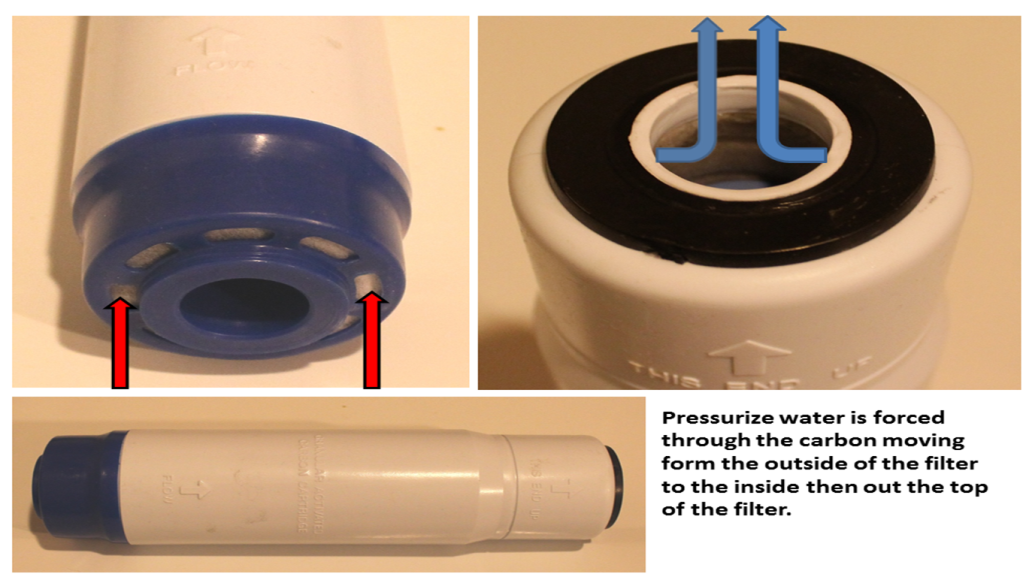

Stage 2: Granular Activate Carbon

The Carbon filter is next stage (2nd stage) of filtration the water will pass through. Water will pass through this filter just the same as the sediment filter.Most carbon filters will pick up about 90 to 95% of all the organic particles and remove most of chlorine and at least some of the chloramines. Pressurized water will move through the carbon filter from the outside into the center of the filter and then to the next stage of filtration, the RO membrane. It will also remove other impurities such as toxins, chemical impurities, and additives used by your local water department (just to name some examples). There are also a few different types of carbon out there to choose from. The granular activated carbon is one of the two more popular types of carbon to find in RO units (the second most popular type is discussed later). A properly maintained carbon filter will help the long term efficiency of the RO membrane and keep replacement costs down. A granular activated carbon filter can last from 4 to 6 months depending on the quality of your water supply, the quality of the carbon, and your usage. As with almost any type of filtration system, if you get better quality carbon you will get better quality water.

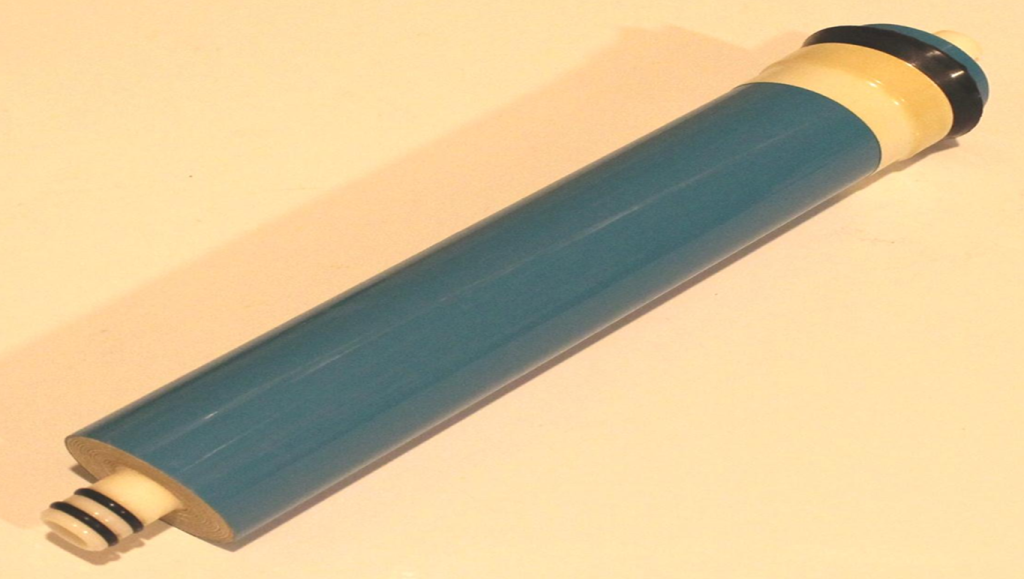

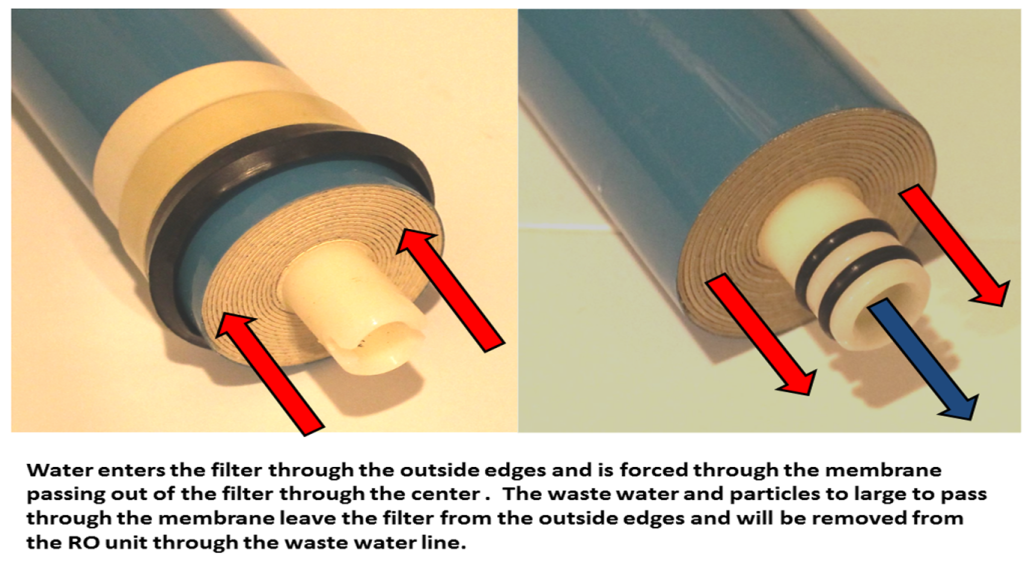

Stage 3 RO Membrane

Then the third stage of filtration is the RO membrane. This is main filter of any RO system. The fine membrane acts as surface filter with fine enough mesh to pass only a small amount of minerals and water molecules through it. Any long chain organic compound, including micro-organisms and also artificial compounds such as pesticides and herbicides will be screened out. Because of the ultra fine mesh size of the membrane, it will also block all harmful virus and other micro-organisms which may pass through in case of alternative filtration technology.

Reverse Osmosis typically employs a membrane with less than 5 angstrom (1 angstrom = 1/10,000,000th meter compare with human hair which is 750,000 angstrom diameter on average). Compare with size of virus which has size in the range of 90 to 1000 angstrom, size of bacteria, which has size in the range of 2000 to 2,000,000 Angstrom, the reverse osmosis membrane technology when installed properly and used with check valve can effectively sterilized the water.

RO units are normally based upon one of two membrane technologies: cellulose triacetate (CTA) and thin film composite (TFC). CTA based systems are typically cheaper and do not filter as well (90-95% rejection rates). TFC based systems cost more but have higher pollutant rejection rates (95%-98%). CTA membranes break down over time due to bacterial attack whereas TFC membranes are more or less impervious to this. CTA units are not recommended for reef tank purposes. TFC membranes are very sensitive chemically to the chlorine found in most water supplies. It is therefore very important to regularly replace the carbon block pre-filter associated with all better-grade TFC systems. TFC membranes are damaged by chlorine so a properly functioning GAC prefilter is mandatory.

A RO membrane can last from 1 to 2 years depending on: the type and quality of your carbon and sediment filter used before the membrane, the quality of your water supply, and your overall usage. Whether or not you back flush your system can also effect the life span of your membrane ( the porcess commonly referred to as back flushing and discuss latter on in this article). As with almost any type of filtration system, if you get better quality membrane you will get better quality water.

Stage 4 Granular Activated Carbon

The fourth and final stage is another granular activated carbon filter. There are sometimes small odors in the clean water which is a result of the interior finishing of the water tank and inner lining of the tubing. Thus a final post carbon filter is normally added as a final polish filter to remove such odors or taste. A carbon filter placed after a RO membrane can last from 8 to 10 months

Storage Tank

Although this is not a part of the filtration, I thought I would mention it anyways as most RO systems have a storage tank. Because of the high pressure drop of the Reverse Osmosis the clean water stream has very slow flow rate. A temporary water reservoir tank is used to buffer the flow when no clean water is drawn from the system. An automatic shut off valve (Which can be electronic or mechanical) is then used to shut off water supply to the RO system when the water tank is full. Some systems do not use a storage tank, but have a booster pump instead.

The pump provides extra water pressure to the system increasing the flow coming out of the system and eliminating the need for a storage tank. Whether or not you choose a system with or without a storage tank would depend upon if you have a GFI electrical outlet close enough to where you will be setting up you RO system and if you want to spend the extra money on a system with a booster pump.

This would describe a typical RO unit sold for household use. IMO, it would provide you with a really good improved water quality for use in your home. But I also feel this set-up has a few drawbacks that I personally do not like: There only are two stages of filtration before the RO membrane resulting in reduced RO member life. There is no stage of filtration after the RO membrane to catch the remaining particles that get through the membrane, and placing a carbon filter after the membrane will only help to improve the taste and smell (assuming those two situations exist) doing nothing for any TDS that my get past the membrane. When I originally had my RO unit set up like the above unit, I had around 4 to 2 ppm of Total Dissolved Solids (TDS) in the water coming out of the unit (my tap water has ~150ppm). After researching how to get 0ppm of TDS, I set up/modified my RO unit which is pictured and described below. This was my approach to produce the most pure water that I could. This system consistently produces water with 0 ppm of TDS. I reconfigured the sequence of the carbon filters, and add a Deionization resin cartridge which seemed to be the most economical approach to getting a really good RO/DI water.

No Change to Stage 1 and 2

When comparing this to the typical off the shelf house hold use filter system, only the first two stages remain the same or at least in the same order. There is a sediment filter followed by a granular activated carbon filter

Stage 3: Catalytic Granular Activated Carbon (additional stage)

The use of two carbon filters (one after the other) can sometimes be required due to the water source conditions including chlorine concentration, organic content and chloramines. In my case, I wanted a higher quality carbon (higher quality than regular granular activated carbon) that will handle the chloramines in our water supply and not let it get to the membrane filter. Not all of the carbon filters in the 2nd or 4th stages of your average 4 stage RO filter will separate the chloramines molecule into its small components of chlorine and ammonia molecules. Some will leave at least some of chlorine to be removed by the RO membrane. As the chlorine is a larger molecule, your membrane will not last as nearly as long until it becomes clogged and ineffective.

Catalytic Granular Activated Carbon is a type of Granular activated carbon (as previously discussed as the second stage of filtration). Carbon filters which are made with catalytic granular activated carbon are much more aggressive than regular carbon. It has a greater ability to break the bond between ammonia and chlorine, and then remove the chlorine before the water enters the RO membrane. A catalytic granular activated carbon filter can last anywhere from 4 to 8 months depending on the quality of the tap water and usage

The 4th stage is still the RO Membrane (unchanged)

Same RO membrane as discussed before

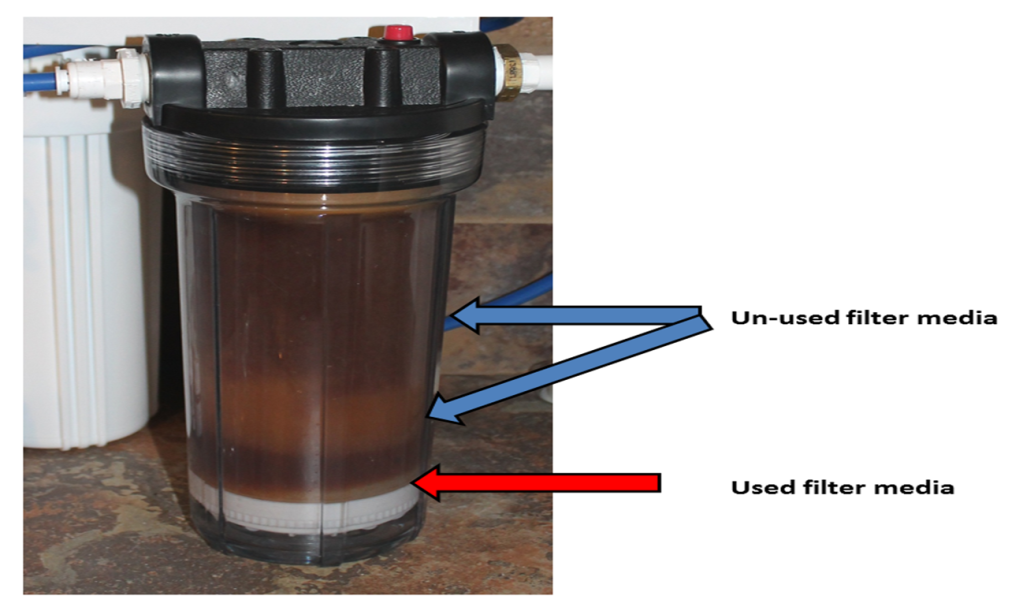

The 5th Stage: The De-ionization (DI) Cartridge

DI cartridges come in two basic varieties: mixed bed and separate bed. Two media chambers are commonly used in separate bed units, one for anion resins (to filter negatively charged ions), the other for cation resins (to filter positively charged ions). Mixed bed units use a single chamber with a mix of anion and cation resins. Mixed bed units seem to be more commonly used. Water production rates for DI units varies, but is typically around 10-15 gallons/hour. DI units are 100% water efficient with no waste water. They are most commonly rated in terms of grains of capacity (a grain is 0.065 grams). Once the capacity of the unit is reached it either needs to be replaced or recharged (using strong acids and bases). Recharging is normally only an option for separate bed units.

Some contaminants captured by a DI cartridge may get past the cartridge long before the unit indicates its capacity has been reached. Silica is a good example of this. What happens is that silica is loosely bound to the resins initially, but is replaced by stronger binding materials like carbonates as the resins become exhausted. The use of two DI units (one right after the other) will allow you to overcome this potential problem. A good quality DI cartridge will remove ammonia, just to name one example. Once I have the money for it, I will be adding a second DI cartridge to my unit DI cartridges can last anywhere from 8 to 18 months depending on the effectiveness of your RO membrane.

The filter media (visible through the clear plastic case) will change color once the media is full of particles and cannot accept any more. The below pic shows what an example can look like based only on my DI filter. You can it starting to turn a very light color at the bottom as the media fills up. This picture was taken only 2 months after the filter was replaced.

Some hobbyists will also set-up an auto top-off system for their aquarium as a part of their RO/DI unit. This will extend the life of your DI stage as it will only be used for the aquarium top-off water and not the household drinking water.

A few more thoughts about RO systems and uses RO or RO/DI water.

RO or RO/DI Water in Aquariums

In marine and reef set-ups, the RO or RO/DI water is mixed with salt (or reef crystals) to provide higher quality salt water. The salt adds back the required trace elements, salts, and minerals necessary to maintain the different forms of marine life. Using pure water can help to eliminate many unsightly problems that can be encountered when using tap water resulting from impurities like: phosphates, nitrates and silicates. Many of these impurities provide required food for undesirable bacteria and several forms of nasty algae. For discus and other soft water fish, the RO or RO/DI water is reconstituted by adding the trace elements and minerals back into the water. In some cases, filtered tap water is carefully blended with the RO water until the correct hardness is achieved. This will give you softer water with a proper ph level. If the tap water is unfiltered a good quality dechlorinator must be used.

Storage of RO or RO/DI water

Often food grade barrels are used to store RO or RO/DI water until it is needed. These food grade barrels are more expensive than trash cans or other containers, which may have various chemicals including mildew retardants added to them during manufacture. Garden hose have been said to be unsafe due to the chemicals used in many of them. Some may be okay but it is a risk not worth taking (IMO). I use clear poly tubing for moving water. Whatever type of storage container you choose to use; the container should have constant aeration and a heater to maintain a constant temp.

Auto Shut-off valve

Not all RO systems have an auto shut off valves. Many people order RO units from mail order companies which refer to the auto shut-off valve as an add-on option. Installing the auto shut off valve on the RO unit simply involves cutting all tubing and installing the valve in as recommended by the manufacture. Any a RO unit that is set-up to also store water in a barrel (or in the typical storage tank that comes with most units), will required an auto shut-off valve. Make sure you know if you are getting an auto shut off valve or not.

RO, RO/DI Unit Maintenance

On a regular basis the storage barrel should be cleaned. This should also be done to your canister housings when replacing cartridges. To clean filter housings scrub well with a weak vinegar and RO water solution followed by rinsing with RO water. The clear tubing can easily be cleaned periodically by submersing for a few hours in a 5 gallon bucket with hydrogen peroxide/RO water mixture followed by a good rinse in RO water.

When the RO unit has only a light demand placed on the membrane it will easily keep a standard 3 to 5 gallon drinking water storage tank topped off as water is used. However, when the RO unit is also used for other applications and/or is used to fill larger storage barrels, the membrane is placed under a heavy demand. In the case heavy demand you should flush the RO membrane on a regular basis. This is often commonly referred to as back-flushing the membrane although that is not a very accurate description of the process. This just involves opening a valve (or flow restricter) on the waste water line for 3 to 5 minutes to flush built up mineral deposits off of the membrane. The information you got with your filter will show you how to complete this. Not all manufactures will have a valve that you can manually open either. You need to check for that before you purchase your system.

The storage tanks will typically required some type of maintenance as well. As different manufactures make their tanks a little different, you should consult your owner’s manual for any required maintenance.

RO system performance For a standard 4 stage set-up as previously discussed you can expect fairly good performance depending on your water quality (tap water) and your maintenance routine. You should expect the produced filtered water to have 10 to 5 ppm or less of TDS. For most marine set-ups this would be very good water to use. For a 5 stage set-up as such as the one that I have and previously discussed, you can expect excellent performance depending on your water quality and maintenance routine. You should expect the produced filtered water to have 0ppm of TDS consistently. This would be the best quality of water to use. As for TDS meters, I have used and would suggest the below two options for you to consider

http://www.aquaticcommunity.com/review/showproduct.php?product=499&limit=recent

And a parting picture of my RO/DI unit

As the valve on the wast line can not be manually opened to flush the membrane (darn valve is stuck closed), I added a by-pass valve. I also added a second line for the RO/DI water (as see at the top of the pic). This makes filling my mixed SW container a lot easier for me. I have a 1/2″ hose I connect to line, place the other end in the SW storage container, and open the valve. After a couple of hours I’m ready to make some SW. As this system is rated at 75 gallons per day, I can fill my 35 gallon container in around 12 to 14 hours. The only future up-grade that I would like to do is adding a booster pump, but that can wait.

I did not permanently hook up my RO/DI unit as my employer could transfer me at any time. I connected the unit to the cold water line running to the utility sink using a quick-connect “T” fitting and just placed the wast water line in the drain. This also allows me to recycle the waste water in the summer time using it to water our flowerbeds and other outside plants

Please feel free to start a thread in the forum to ask any questions you may have. If you are not already a member, you will need to sign-up first.

http://www.aquaticcommunity.com/aquariumforum/forumdisplay.php?f=62

Very good Cliff, excellent reference.

Dave

ThankYou. Super articles

Thank You,Thank You,Thank You Cliff,just very helpfull article.

Mohsen

Glad to read you liked it

Just wondering if using the boxed ocean water would be equal to using an Ro-DI system with the reef crystals ?

No not equal, just different depending on were you are